Manufacturing On Demand

We Print Everything From Manufacturing Tools To Patient Implants - 365 Days A Year

We Specialise In

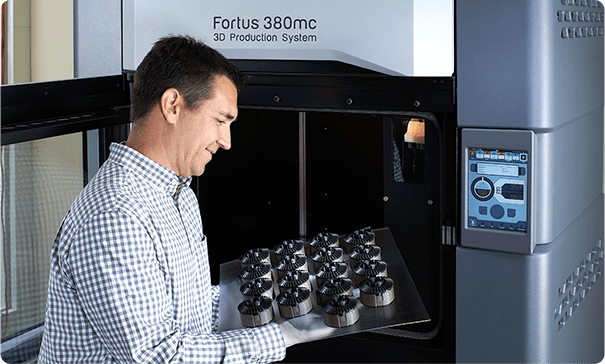

3D Printing

Print the right part for the job

CAD File Optimisation

Optimised to maximise functionality

Part Finishing

We offer specialist advice on the best finishes for your part

Project Consulting

We help you choose the perfect material for your project

Protect Your Intellectual Property

We offer NDA to protect the privacy of your design

We go to great lengths to ensure that your privacy is protected. From offering NDA’s to our private printing area, we are equipped with what it takes to protect your IP.

Benefits of 3D Printing Traditional Manufacturing

- Reliable Quality

- Fast Turnaround

- Reduce Assembly Time & Cost

- Range Of Materials

- Testing & Validating

Reliable Quality

Team of Dedicated application engineers who use the technology daily is how we can guarantee our clients reliable quality, 100% of the time.

Fast Turnaround

Even with multiple iterations, we can deliver your 3D printed part directly to your door in 48 hours or less.

*Subjective to technology, material & build size

Reduce Assembly Time & Cost

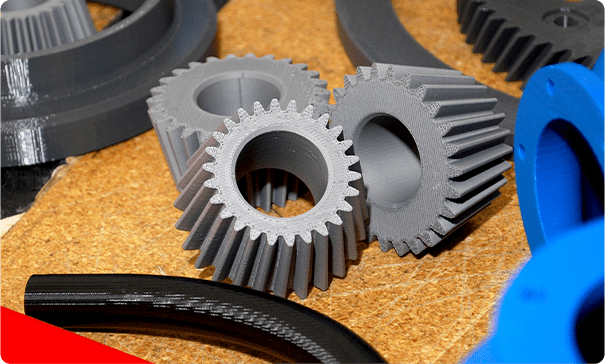

Print intricate designs & complex geometries in less time and for less cost with additive manufacturing.

Extensive Range Of Materials

Don't be limited by traditional manufacturing. Choose from print using a variety of different material categories and experience design freedom.

- FDM THERMOPLASTICS

- POLY PHOTOPOLYMERS

- METAL alloy

- DESKTOP METAL

- LITHOZ CERAMIC

- FDM THERMOPLASTICS

- POLY PHOTOPOLYMERS

- METAL alloy

- DESKTOP METAL

- LITHOZ CERAMIC

Testing & Validating

Showcase your ideas to the board or present working prototypes to your team before your part goes to production with 3D printed prototypes.

Reliable Quality

Team of Dedicated application engineers who use the technology daily is how we can guarantee our clients reliable quality, 100% of the time.

Fast Turnaround

Even with multiple iterations, we can deliver your 3D printed part directly to your door in 48 hours or less.

*Subjective to technology, material & build size

Reduce Assembly Time & Cost

Print intricate designs & complex geometries in less time and for less cost with additive manufacturing.

Extensive Range Of Materials

Don't be limited by traditional manufacturing. Choose from print using a variety of different material categories and experience design freedom.

- FDM THERMOPLASTICS

- POLY PHOTOPOLYMERS

- METAL alloy

- DESKTOP METAL

- LITHOZ CERAMIC

- FDM THERMOPLASTICS

- POLY PHOTOPOLYMERS

- METAL alloy

- DESKTOP METAL

- LITHOZ CERAMIC

Testing & Validating

Showcase your ideas to the board or present working prototypes to your team before your part goes to production with 3D printed prototypes.

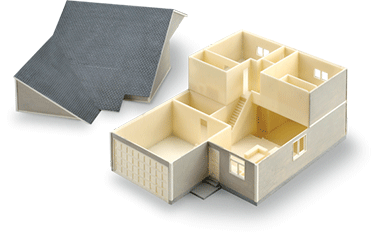

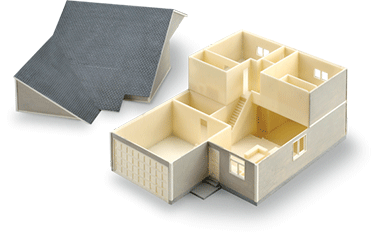

What We Can Help You Produce

-

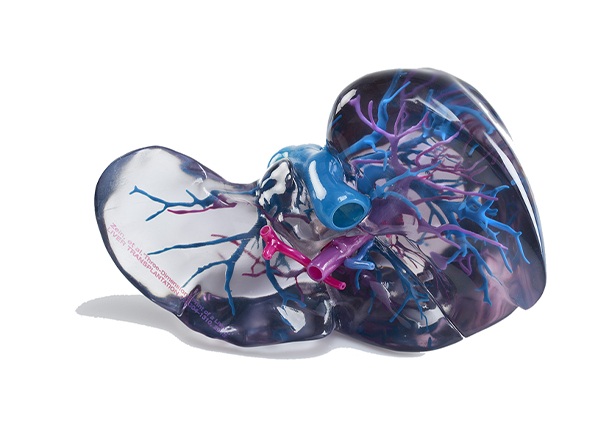

Anatomical Models

Anatomical Models -

Functional Prototypes

Functional Prototypes -

Concept Models

Concept Models -

ECS Ducts

ECS Ducts -

Forming Tools

Forming Tools -

Jigs & Fixtures

Jigs & Fixtures -

Composite Tooling

Composite Tooling -

Patient- Specific Implants

Patient- Specific Implants

Anatomical Models

Anatomical Models

- Custom on-demand models

- Short lead times

- Multiple colours & materials

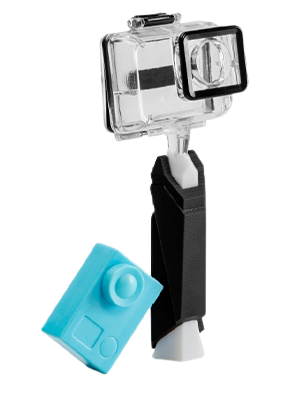

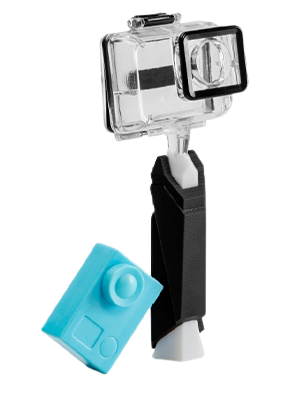

Functional Prototypes

Functional Prototypes

- Quick turn functional prototypes

- Go-to solution for design iteration & testing

- Meet strict deadlines

Concept Models

Concept Models

- Low cost & quick to produce

- Predict market success with real world feedback

- Lead times as little as 24 hours

ECS Ducts

ECS Ducts

- Achieve desired configuration

- Reduce long lead times

- No additional tooling

Forming Tools

Forming Tools

- Extreme heat resistant materials

- Update designs instantly

- Produce in less time

Jigs & Fixtures

Jigs & Fixtures

- High strength plastics

- Designed for optimal performance

- Reduce labour cost

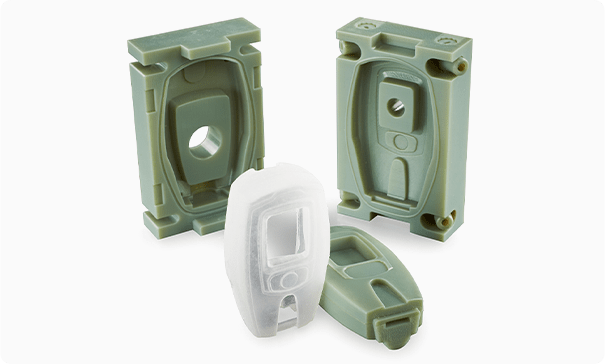

Composite Tooling

Composite Tooling

- Up to 90% cost savings

- Low volume tooling

- Tailored to your design

Patient-Specific Implants

Patient-Specific Implants

- Supreme accuracy to ensure best fitting solution

- Complex geometries with reduced lead times

- Streamline workflow

Anatomical Models

Anatomical Models

- Custom on-demand models

- Short lead times

- Multiple colours & materials

Functional Prototypes

Functional Prototypes

- Quick turn functional prototypes

- Go-to solution for design iteration & testing

- Meet strict deadlines

Concept Models

Concept Models

- Low cost & quick to produce

- Predict market success with real world feedback

- Lead times as little as 24 hours

ECS Ducts

ECS Ducts

- Achieve desired configuration

- Reduce long lead times

- No additional tooling

Forming Tools

Forming Tools

- Extreme heat resistant materials

- Update designs instantly

- Produce in less time

Jigs & Fixtures

Jigs & Fixtures

- High strength plastics

- Designed for optimal performance

- Reduce labour cost

Composite Tooling

Composite Tooling

- Up to 90% cost savings

- Low volume tooling

- Tailored to your design

Patient-Specific Implants

Patient-Specific Implants

- Supreme accuracy to ensure best fitting solution

- Complex geometries with reduced lead times

- Streamline workflow

We Work With The Best

Cutting Edge Materials

I want to print using

- Selective Laser Sintering

- Fused Deposition Modeling

- Polyjet

- Direct Metal Laser Sintering

- Selection Absorption Fusion

Selective Laser Sintering

Build complex parts directly from 3D CAD data via a heat laser that fuses or sinters powdered thermoplastics. SLS is an affordable way to build durable production parts in low volume.

- Nylon 12 AF

- Nylon 12 GF

- Nylon 12 PA

- Nylon 12 FR

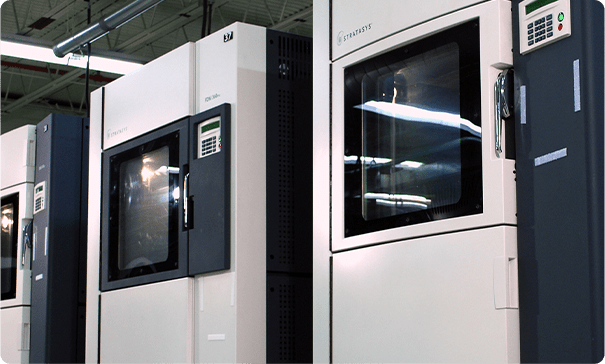

Fused Deposition Modeling

FDM parts are printed layer by layer and the technology works with production-grade thermoplastics to build tough, durable parts that are accurate, repeatable and stable over time. FDM is great for concept models, prototypes, tools & production parts.

- ABS

- ASA

- PC

- ULTEM

- NYLON

- ANTERRO

Polyjet

Polyjet is excellent for realistic, high resolutions models and prototypes, that convey final-product aesthetic. Polyjet is a process that jets and cures thin layers of photopolymer with UV energy that allows manufacturers, designers & engineers to achieve complex shapes, intricate details and delicate features.

- VeroWhitePlus

- Polyjet GreenFire

- VeroBlue

- VeroGray

- VeroClear

- PolyJet Amber Clear

- Rigur

- PolyJet Flex & Over Mold

- Polyjet TangoPlus

Direct Metal Laser Sintering

Create high-precision mechanically and thermally resilient metallic components in a range of metal and alloy materials. Parts that are required to be complex, dense, corrosive resistant, and high-strength, can be printed for less cost in less time.

- Stainless Steel

- Aluminum

- Inconel

- Titanium

- Cobalt

Selection Absorption Fusion

Produce small to medium functional parts with tighter tolerances, and deliver accurate, consistent, and repeatable parts with engineering-grade thermoplastic materials.

- High Yield PA 11

Print My Part In 3 Simple Steps

Step 1

Step 3

97% Of Clients Choose To Work With Us Again For Good Reason

No more time & money wasted in failed builds. Our team of dedicated application engineers applies their specialist knowledge to ensure your project meets its desired requirements, is designed correctly for its application, meets strict deadlines, and is printed right the first time.

With over 5 categories of specialised 3D printing materials available, we give you the choice of ‘testing’ and selecting the best materials for your application. All of our materials are stored in our hub, ready to be used.

Objective3D is an ISO 9001 certified company, committed to providing quality service to our customers. We believe that quality assurance is the prerequisite for success in additive manufacturing. We continuously assess your project during each vital stage of the process, ensuring we deliver you an exceptional final product.

We recognise the importance of protecting your ideas. That’s why we’ve gone to great lengths and put in place several layers of IP security to keep your creations safe. NDA agreements, a secured printing room, and a dedicated application engineer are just some of the ways we can protect your designs.

3D printing is not merely an add-on product to our existing business. It’s our number 1 priority, all day, every day. Unlike other 3D printing hubs, we are daily users of the technology. We pride ourselves on gaining a deeper understanding of how each technology works and use our findings to better service our clients.

If for some reason we’re unable to fulfil your project, don’t worry about searching for another 3D printing hub, we can still ensure your part is printed. Our partnership with Stratasys Global network means we can utilise their resources, have your project fulfilled and sent directly to your door.

Being one of Australia’s largest 3D printing providers, we give you access to world class machinery and manufacturing tooling without the overhead cost. With over 10+ technologies from you to choose from, there’s literally nothing we can’t print.

Frequently Asked Questions

Yes, we do. Once an NDA agreement is signed, we print and finish your part in a secure room that is not accessible to anyone other than your designated engineer.

Yes, we can do both. When we send you your quote, you can pay online by accessing our unique payment link or you can contact us and pay over the phone.